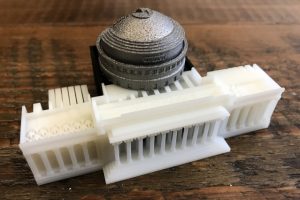

A new online course from MIT and Boeing uses a 3-D-printed kit to enrich the learning experience. Similar to a textbook, the kit is used as a reference throughout the course. The kit has metal and polymer parts made by industry-relevant 3-D-printing processes, including stereo-lithography, multi-jet fusion, and direct metal laser sintering. The parts interlock to form a model of MIT’s iconic Building 10 dome.

Additive manufacturing (AM), also known as 3-D printing, is poised to transform product design, manufacturing, and maintenance. However, limited knowledge of the fundamental principles, applications, and business implications of AM is a barrier to its broad and rapid adoption. To help professionals and organizations realize AM’s potential and accelerate its use, MIT and Boeing are collaborating on a new online course for professionals: Additive Manufacturing for Innovative Design and Production.

This nine-week online course explores the transformational capabilities of AM in the design, production, and service of products, and investigates its implications in restructuring production workflows and lowering manufacturing costs. Geared towards industry professionals, the new course teaches critical skills that prepare employees to implement AM in their organisations. The course explains leading AM technologies for polymers, metals, and advanced materials; addresses design for AM via both engineering principles and computational design; and includes quantitative models for assessing the cost and value of components made by AM.