Produced by Guest blogger

Produced by Guest blogger

Current student Doyin, who is studying MA Advertising – recently attended a free industry visit to LUSH – a multi-million pound international cosmetics company – as part of the Graduate Skills Programme run by CareersBU

I visited the LUSH facility and offices with a few other interested BU students to learn everything there is to know about LUSH through fantastic presentations from staff and the chance to learn about career opportunities.

The Bournemouth University Graduate Skills + Award team and the Lush team collaborated to create this programme. Lush is a multimillion-dollar international cosmetics company that has its UK headquarters and Factory in Poole, Dorset – which is located near to Bournemouth University.

The tour of the organisation’s production facilities was guided by Victoria Meers, the organisation’s talent lead. We started at the Hot Desk, where all of Lush’s artwork is made, and then went on a lab tour. I had never considered that a cardboard engineer was required to produce brand packaging. Andrew Petty, one of the engineers, revealed how the cardboards are created; from designing to cutting out and folding by hand.

The attention to detail does not stop there; for each Lush store around the world, a caricature of the store is always built up in the Mock Shop department to visualise every detail before building and launching the store.

Other intriguing teams include the R and D team, which builds a product through research and development, and the Testing team, led by Jet Shears, who provided valuable insight into how Lush product testing works. Lush has studied over 300 testers in various age groups and with diverse skin types.

Lush recently launched The Lush Green Hub, a structure worth around 25 billion pounds dedicated to reuse, recycling, and repurposing, and we also got a sneak peek inside this sustainable nirvana. The company has a buyer products programme, which allows buyers to return containers of used products and earn 50p back. The Green Hub is used not just to recycle old product packaging, but also to ensure that water, furnishings in their stores, and excess products are not put to waste. This was wonderful to see, especially now where greenwashing has become the norm among brands.

Lush used about 600 raw ingredients as of 2022. The brains behind this are Morgan Brown, Abi Whisken, Pendle Hill, and Ashlyn Higham; they source and handle all the materials. Although they strive to purchase locally whenever feasible to limit their carbon footprint, they also source globally and the benefits of their purchasing have aided in the improvement of certain areas. This social impact movement has been wonderfully incorporated into their technological system; in fact, they recently severed ties with Google to boost smaller tech companies instead.

Aside from the numerous career opportunities offered by Lush, I learnt that the company is 10% employee owned, making them a part of the business.

Overall, it’s safe to say that the office atmosphere at Lush is something you want to experience every day. The design is simple yet cheery, colourful without being over the top, and it smells amazing throughout.

It was such an eye-opening day for me; 25 years in business and Lush does not appear to be slowing down anytime soon.

My journey to win 50% tuition fee discount – my postgraduate scholarship story at Bournemouth University

My journey to win 50% tuition fee discount – my postgraduate scholarship story at Bournemouth University What next? Deciding your Career Path after Graduating from BU Law.

What next? Deciding your Career Path after Graduating from BU Law. Understand the UK job market – tips from BU Career team to prepare for my future job

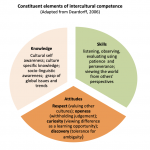

Understand the UK job market – tips from BU Career team to prepare for my future job Opportunities to build intercultural competence while studying at Bournemouth University

Opportunities to build intercultural competence while studying at Bournemouth University